Qaadista birta ee joogtada ahi waa dhakhso, badbaado iyo hab fudud oo kor loogu qaado taarikada birta, baloogyada birta iyo qalabka birta ee cylindrical, sida qaybaha makaanikada, caaryada feerka iyo noocyada kala duwan ee alaabta birta ah.

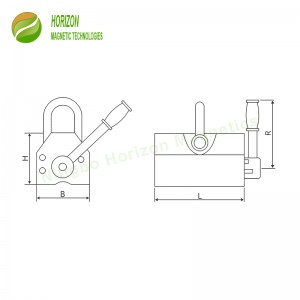

Waxay ka kooban tahay laba qaybood, nuugista joogtada ah iyo qalabka dheecaanka. Nuugista joogtada ahi waxay ka kooban tahay Neodymium magnets joogto ah iyo saxan magnet-conductive ah. Xadhkaha xoogga magnetic-ka ee ay abuuraan magnets Neodymium waxay maraan saxanka magnet-conductive, alaabta soo jiidata waxayna sameeyaan wareeg xiran si loo gaaro ujeedada qaadista alaabta birta ah. Aaladda soo dayntu waxay inta badan tixraacaysaa gacanta. Waxaa si weyn loogu isticmaalaa warshadaha mishiinada, wax soo saarka caaryada, bakhaarada iyo waaxaha gaadiidka si loo qaado taarikada birta, birta birta ah iyo walxaha kale ee birta ah.

1.Xajmiga is haysta iyo miisaanka fudud

2.Quick iyo fududahay in lagu shaqeeyo nidaamka ON / OFF / gacanta

3.V-qaabeeya naqshad jeexdin ah ee hoose oo awood u siinaya isla magnet wiish ku habboon walxaha siman iyo wareegsan labadaba.

4.Force ku shaqeeya darajada aad u xoog badan ee dhul dhif ah Neodymium magnets

5.Large chamfering agagaarka hoose si wax ku ool ah u ilaalinaya flatness ee dusha hoose iyo jidaynayey wiish magnetic in ay si buuxda u dhaqmaan ay xoog magnetic.

| Lambarka Qaybta | Lagu Qiimeeyay Xoog Qaadista | Xoogga Jiid ee ugu badan | L | B | H | R | Miisaanka saafiga ah | Heerkulka shaqada ee ugu badan | |

| kg | kg | mm | mm | mm | mm | kg | °C | °F | |

| PML-100 | 100 | 250 | 92 | 65 | 69 | 155 | 2.5 | 80 | 176 |

| PML-200 | 200 | 550 | 130 | 65 | 69 | 155 | 3.5 | 80 | 176 |

| PML-300 | 300 | 1000 | 165 | 95 | 95 | 200 | 10.0 | 80 | 176 |

| PML-600 | 600 | 1500 | 210 | 115 | 116 | 230 | 19.0 | 80 | 176 |

| PML-1000 | 1000 | 2500 | 260 | 135 | 140 | 255 | 35.0 | 80 | 176 |

| PML-1500 | 1500 | 3600 | 340 | 135 | 140 | 255 | 45.0 | 80 | 176 |

| PML-2000 | 2000 | 4500 | 356 | 160 | 168 | 320 | 65.0 | 80 | 176 |

| PML-3000 | 3000 | 6300 | 444 | 160 | 166 | 380 | 85.0 | 80 | 176 |

| PML-4000 | 4000 | 8200 | 520 | 175 | 175 | 550 | 150.0 | 80 | 176 |

| PML-5000 | 5000 | 11000 | 620 | 220 | 220 | 600 | 210.0 | 80 | 176 |

1. Ka hor inta aanad qaadin, nadiifi dusha sare ee shaqada si loo qaado. Xariiqda dhexe ee birlabka qaadista joogtada ah waa in ay ku beegan tahay bartamaha cuf-jiidka shaqada.

2. Habka qaadista, culeyska xad dhaafka ah, dadka ka hooseeya qalabka shaqada ama gariirka daran waa mamnuuc. Heerkulka qaybta shaqada iyo heerkulka deegaanku waa inuu ka hooseeyaa 80C darajo.

3. Marka la qaadayo workpiece cylindrical, V-groove iyo workpiece waa in lagu hayaa xiriir la laba xariiq oo toosan. Awoodeeda wax qaadistu waa 30% - 50% ee awooda wax qaadis ee la qiimeeyay.