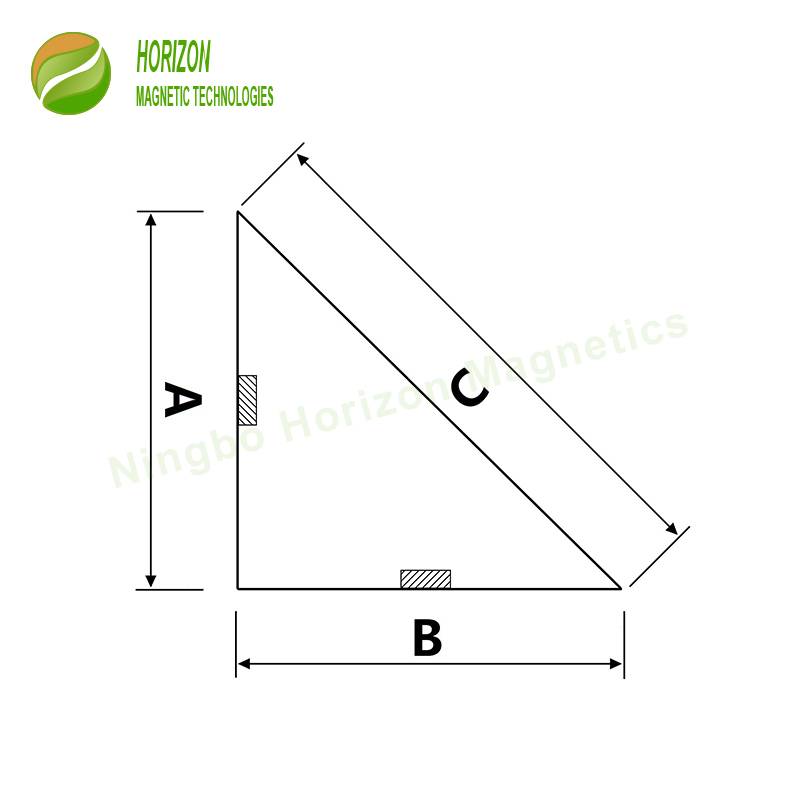

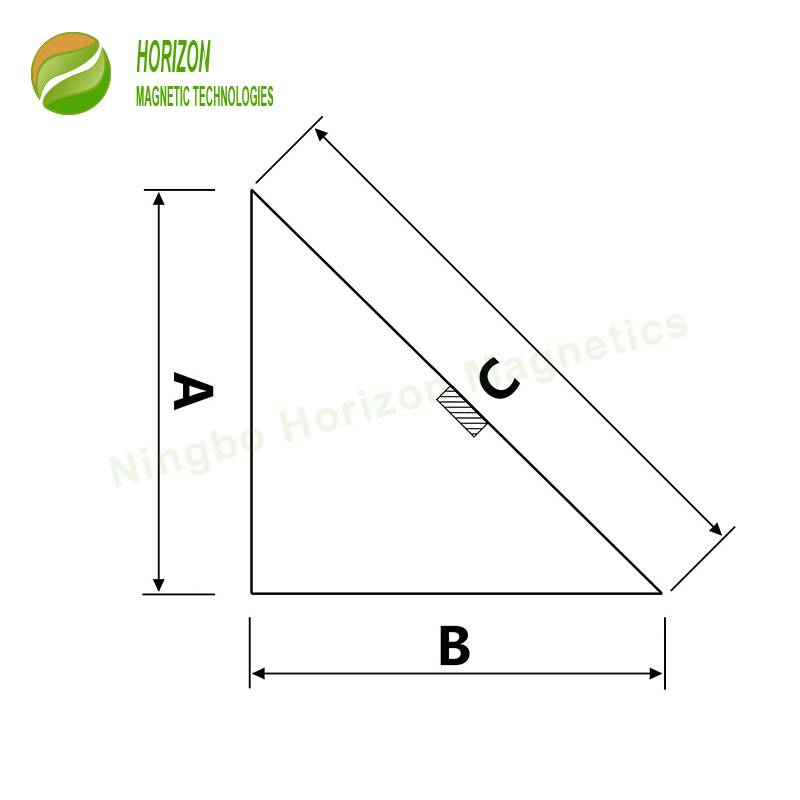

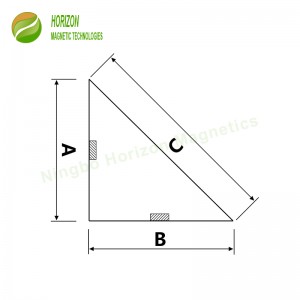

Waxay ka samaysan tahay xoogNeodymium bar magnetsgundhig birta tayada sare leh. Sida qaab dhismeedka iyo mabda'a kanaalka Neodymium magnets, birta waxay dib u habaynaysaa polarity ee magnets Neodymium dhinac ka mid ah dhinaca kale ee la xidhiidha oo leh xoog haynta sare. Waxaa intaa dheer, magnets yar oo badan oo bir ah ayaa ka ilaaliya birta dhaawaca farsamada. Dhinaca xidhiidhka waxa ay suurtogelinaysaa meelaynta degdega ah oo saxda ah ee shaambada birta ee dhismaha qaab-dhismeedka birta iyada oo aan simbiriirixan ama simbiriirixan lahayn. Magnet chamfer waa isosceles saddexagalka saxda ah oo qaabaysan waxaana lagu geyn karaa dhowr cabbir oo kala duwan oo leh magnets hal dhinac ah, laba dhinac ama hypotenuse oo dhererkeedu yahay 100% ama kaliya 50% dhererka.

1. fududahay in lagu shaqeeyo

2. Dib loo isticmaali karo oo waara si loo yareeyo maalgashiga la wadaago muddada fog

3. Ma jiro bilal, boolal, alxan ama koronto lagama maarmaan u ah in lagu xiro chamfer birlabeedka. Degdeg in la dhigo, ka saar oo nadiifi

4. Universal oo leh habab la taaban karo oo la sii dajiyay si loo dhimo tirada iibka iyo kharashka nidaamyada kala duwan

5. Xoog xabag leh oo aad uga xoog badan iyo adeeg ka dheer kan caagagga

6. Hagaajinta natiijada tayada ee alaabta la taaban karo ee la sii daayay si meesha looga saaro inta badan dhibaatooyinka dhamaystirka dhismaha

1. Magnet xoog tartan aan la tartamin iyo codsiga warshadaha la taaban karo ee precast oo aqoon u leh waxa iyo sida loo hubiyo birta birta ah,magnets xiridaoo geli magnets si loo xalliyo welwelka macaamiisha

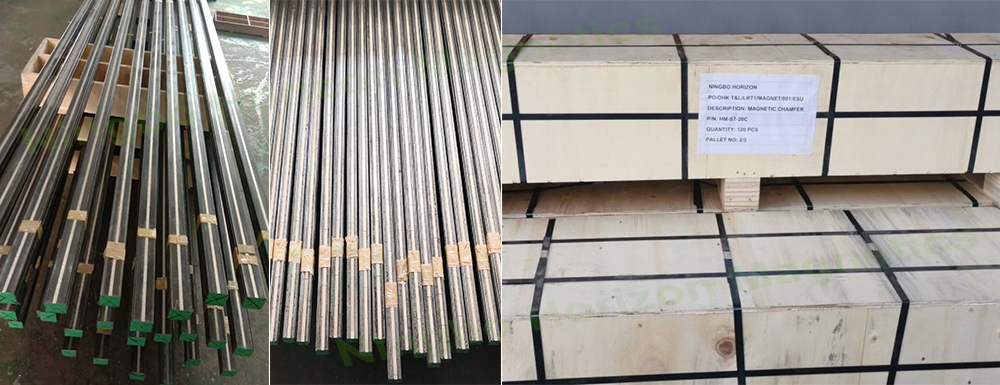

2. Cabirro badan oo la heli karo si loo badbaadiyo kharashka qalabaynta ka dibna qiimaha alaabta macaamiisha

3. Cabbirrada caadiga ah ee kaydka ah oo diyaar u ah bixinta isla markiiba

4. xalal gaar ah oo la heli karo marka la codsado

5. Qalab badan oo birlab ah oo caan ku ah macaamiisha iyo qaar ka mid ah moodooyinkayada ayaa loo aqoonsaday inay yihiin naqshadeynta caadiga ah ama cabbirka warshadaha la taaban karo ee precast.

| Lambarka Qaybta | A | B | C | Dhererka | Dhererka Magnet | Nooca Dhinaca Magnetized | Heerkulka shaqada ee ugu badan | |

| mm | mm | mm | mm | °C | °F | |||

| HM-ST-10A | 10 | 10 | 14 | 3000 | 50% ama 100% | Keli | 80 | 176 |

| HM-ST-10B | 10 | 10 | 14 | 3000 | 50% ama 100% | Labanlaab | 80 | 176 |

| HM-ST-10C | 10 | 10 | 14 | 3000 | 50% ama 100% | Keli | 80 | 176 |

| HM-ST-15A | 15 | 15 | 21 | 3000 | 50% ama 100% | Keli | 80 | 176 |

| HM-ST-15B | 15 | 15 | 21 | 3000 | 50% ama 100% | Labanlaab | 80 | 176 |

| HM-ST-15C | 15 | 15 | 21 | 3000 | 50% ama 100% | Keli | 80 | 176 |

| HM-ST-20A | 20 | 20 | 28 | 3000 | 50% ama 100% | Keli | 80 | 176 |

| HM-ST-20B | 20 | 20 | 28 | 3000 | 50% ama 100% | Labanlaab | 80 | 176 |

| HM-ST-20C | 20 | 20 | 28 | 3000 | 50% ama 100% | Keli | 80 | 176 |

| HM-ST-25A | 25 | 25 | 35 | 3000 | 50% ama 100% | Keli | 80 | 176 |

| HM-ST-25B | 25 | 25 | 35 | 3000 | 50% ama 100% | Labanlaab | 80 | 176 |

1. Si tartiib ah ugu dheji chamfer birlabeedka meelaha qaab-dhismeedka si aad uga fogaato magnets-ka ay waxyeelada soo jiidashada lama filaanka ah.

2. Magnet-ka Neodymium ee ku xidhan waa in la nadiifiyaa. Iska ilaali in aad qariso birlabeedka si aad u ilaaliso xoog birlabeedka.

3. Isticmaalka ka dib, waa in la nadiifiyaa oo la saliidaa si looga ilaaliyo daxalka.

4. Heerkulka shaqada ama kaydinta ugu badan waa inuu ka hooseeyaa 80 ℃. Heerkulka sare ayaa laga yaabaa inuu keeno birlab birlabeedka inuu yareeyo ama gebi ahaanba lumiyo xoogga birlabeedka.

5. In kasta oo xoogga birta birta birta magnetic uu aad uga hooseeyo magnet-ka xirida, haddana waa ku xoog badan tahay in ay khataraha ku abuurto shaqaalaha iyada oo loo marayo qanjaruufo saameyn leh. Xirashada galoofyada si aad u ilaaliso gacmaha ayaa aad loogu talinayaa. Fadlan ka fogee qalabka elegtarooniga ah iyo biraha ferromagnetic-ka aan loo baahnayn. Taxaddar gaar ah waa in la sameeyaa haddii uu qof xidhan yahay qalabka wadnaha garaaca, sababtoo ah meelaha magnetic xooggan waxay dhaawici karaan qalabka elektaroonigga ah ee ku jira qalabka wadnaha.